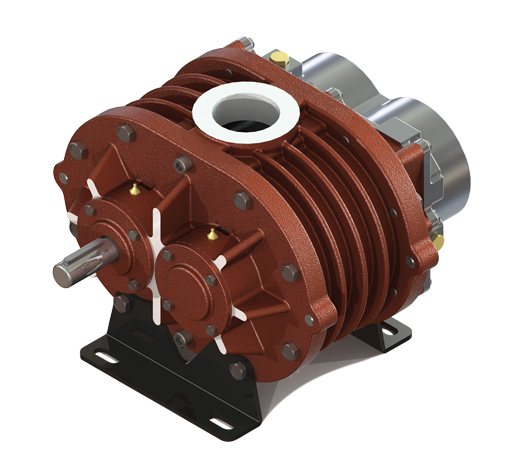

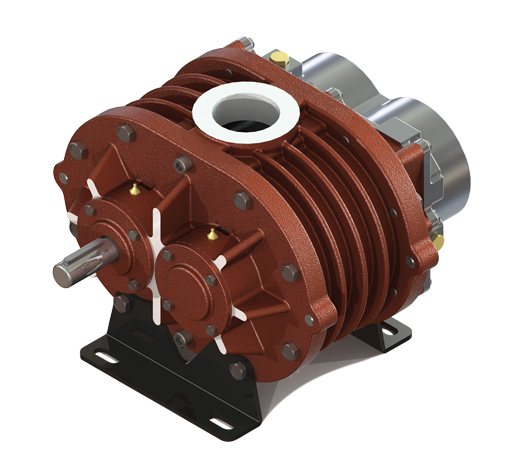

N Series Blower

• Air Flow: Max. 700mᶾ/h • Pressure: Max. 1000 mbar g • Vacuum: Max. -500 mbar g

• Air Flow: Max. 700mᶾ/h • Pressure: Max. 1000 mbar g • Vacuum: Max. -500 mbar g

DETAILS

Rotor of Blower is made of one piece cast iron (GGG50) and has two lobes. It has helical timing gears made of 17CrNiMo6 hardened steel. Blower is lubricated with both splashing grease and sealing is provided by labyrinth type rings. The drive shaft sealing is provided with viton felt. They are heavy operation blowers and designed for long operation periods.

|

Blower set contains a Blower, suction filter with silencer, discharge silencer, check valve, pressure or vacuum safety valve, belt-pulley system, belt-pulley guard, anti-vibration mounts, manometer, filter level indicator, frame and first oil load.

|

|

Compact acoustic cab is completely modular and made of DKP sheet metal. It has external fans and an air circulation helps prevent blower to warm up. It is covered by a fireproof acoustic sponge (NFAF) and can be carried by forklifts.

|

– Pneumatic Transport (dilute phase) of granular materials (pressure and vacuum)

– Water Treatment Procedure at Purification Plants (pressure)

– Pool ventilation in Fish Farms (pressure)

– Central Dust and Fume Extraction system (vacuum)

– Central Milking Machines (vacuum)

– Sandblasting Systems (pressure)

– Drying Systems (pressure)

– Ventilation Systems (pressure and vacuum)

|

N SERIES GENERAL DESIGN Note: RUUT BLOWER reserves the right to change dimensions without notice.

|

N SERIES BLOWER CONFIGURATIONS

|

|

N SERIES ACCESSORIZED BLOWER GENERAL DESIGN Note: RUUT BLOWER reserves the right to change dimensions without notice.

|

N SERIES SPARE PARTS LIST

1. Blower

|

© Copyright TÜYLÜOĞLU Makina İmalat San. Tic. Ltd. Şti. 2018. All Rights Reserved